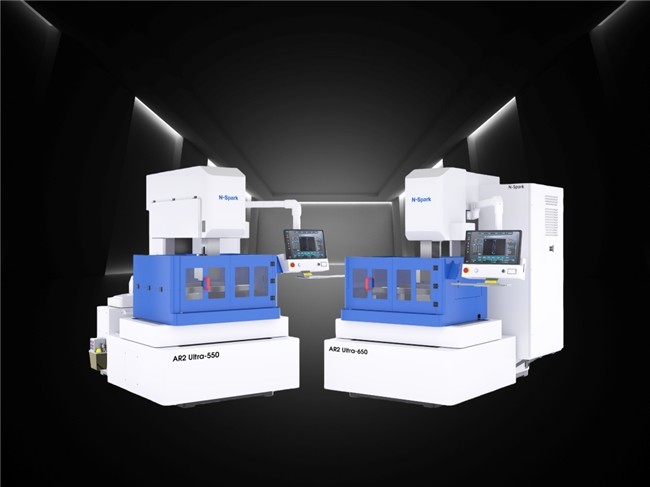

Manual threading is time-consuming, labor-intensive, and prone to precision errors—these are common challenges in machine tool processing. The NOVICK AR2 Ultra automatic threading and molybdenum wire-cut EDM machine tool has undergone comprehensive design upgrades and technological innovations. As a pioneer in online cutting, it has achieved fully automated threading technology, completely breaking the traditional reliance on manual threading in reciprocating molybdenum wire-cut EDM machine. This breakthrough makes the smart manufacturing experience of "threading without manual intervention and processing without constant supervision" a reality.

One-click full hosting – the true smart threading

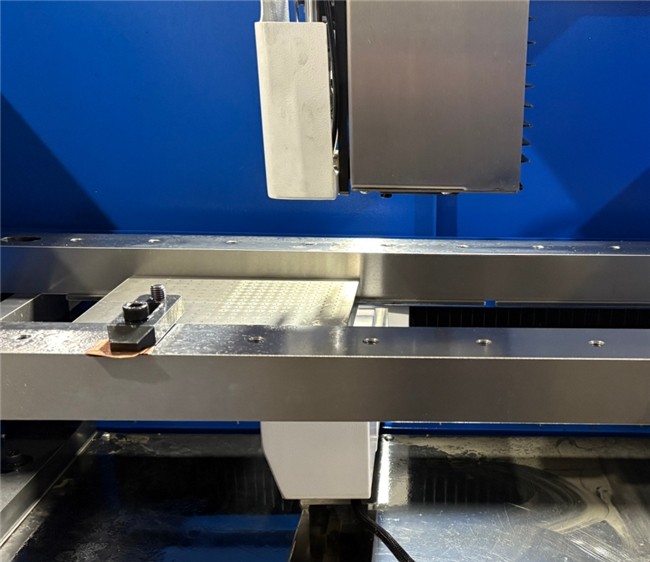

The repetitive manual operations of threading, tensioning, and rewinding wires remain the primary bottleneck for productivity enhancement. The AR2 Ultra by NOVICK features a highly integrated automated design that seamlessly combines these processes into a continuous workflow. ① Automated wire threading function: Fully automated molybdenum wire insertion. ② Automated rewinding: Post-processing automatic wire retrieval. ③ Automated tensioning: Works in tandem with threading/rewinding to automatically adjust to required tension, reducing operator strain. ④ Semi-automated threading assistance: Effectively handles complex threading scenarios, preventing production interruptions caused by wire jamming.

Processing safety and stable reliability are among the most critical concerns for enterprises. The AR2 Ultra features multiple safety and stability mechanisms: it includes wire break protection and locked rotor protection to enhance system safety. Advanced tension monitoring ensures constant tension control, laying a solid foundation for stable processing. A precision threading mechanism guarantees accurate threading. High-quality manufacturing with premium raw materials and meticulous craftsmanship ensures the machine's durability.

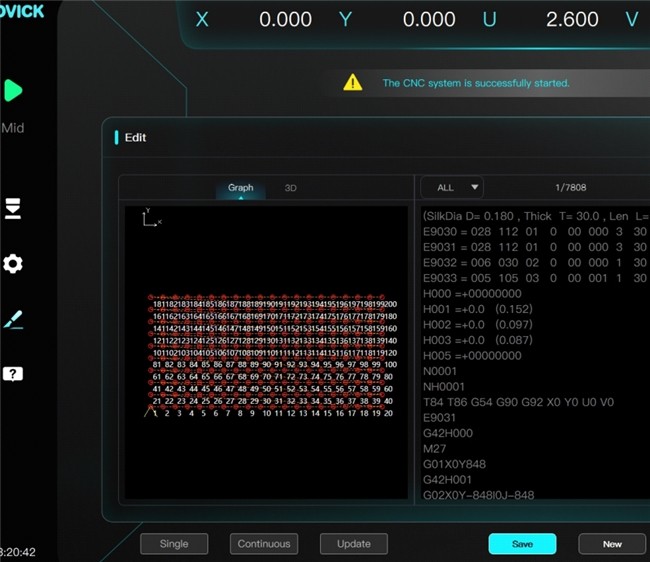

The AR2 Ultra intelligent control system features automatic wire break detection and automatic guide wire cleaning functions to ensure continuous and efficient operation. It also supports automatic step skipping processing and centralized waste removal, maintaining cutting stability throughout the process without manual intervention, truly achieving "hands-off operation upon startup".

Precision and efficiency guaranteed, delivering top-tier performance

The AR2 Ultra achieves automation while maintaining essential performance standards including precision, efficiency, and ease of operation.

High-precision cutting: The AR2 Ultra from NOVICK employs Taiwan's Yintai (PMI)/Shangyin precision linear guides and ball screws, establishing a solid foundation for high mechanical accuracy, machining stability, and excellent repeatable positioning precision. Advanced power supply and full servo control technology, combined with precision mechanical structures, achieve micron-level cutting accuracy, ensuring every product withstands rigorous inspection.

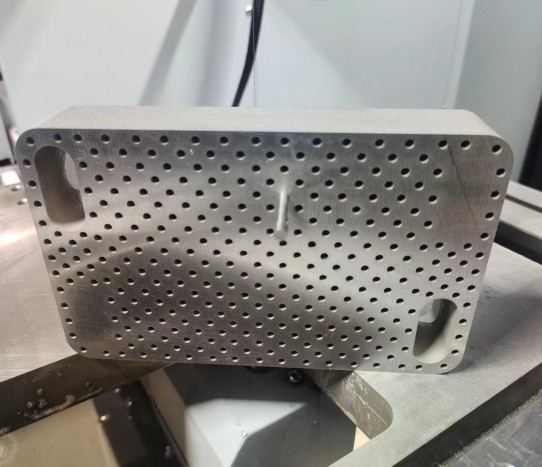

The machining process is stable and efficient: The self-developed pulse power supply precisely controls each discharge pulse, combined with real-time servo adjustment, ensuring stable and efficient operation. This achieves high surface roughness and cutting speed while effectively reducing molybdenum wire consumption. Additionally, the Z-axis CNC configuration enables automatic taper machining, improving precision without manual data calculation, ensuring both speed and accuracy. The centralized waste material collection function, combined with automatic wire threading function, allows unattended processing of multi-cavity templates at night, significantly reducing labor costs and enhancing overall machine utilization.

Enhanced user interaction: The 22-inch HD display paired with a handheld control box ensures intuitive operation. It supports multiple languages and provides a user-friendly software configuration system with categorized processing parameters. Additionally, the system features a convenient historical database, allowing users to access past data for processing at any time, enabling even beginners to quickly get started.

One-click adaptation for diverse materials and complex processes: Features multiple automated programming functions including multi-hole centralized scrap collection, taper machining, localized taper machining, irregular shape machining, chipless machining, and automatic wire threading function. Equipped with a comprehensive preset process parameter library, it optimizes low-loss, high-efficiency cutting solutions for various conductive materials such as steel, copper, aluminum, and cemented carbide.

Multi-industry adaptation, cost reduction and efficiency enhancement are essential

Quality equipment delivers tangible results: saving labor, time, and materials translates to real profits. The NOVICK N-Spark AR2 Ultra automatic wire threading molybdenum wire cut EDM machine achieves intelligent manufacturing goals through fully automated threading, smart programming, high-precision constant tension control, and efficient energy management. It truly embodies the principle of 'machine running continuously when operators pause, materials fully utilized, and time maximized.' Widely applicable across industries including mold manufacturing, aerospace, automotive components, electronics, medical devices, and daily hardware, it excels in high-precision, high-efficiency cutting and processing for conductive metals like steel, copper, and aluminum.

The unmanned night operation feature eliminates the need for workers to stay up late, maximizing equipment utilization. With high automation, it significantly reduces manual intervention, lowering labor costs and physical strain while ensuring consistent product quality and preventing human errors. The integrated design minimizes processing fluid splashing, promoting environmental protection and reducing material waste. The AR2 Ultra automatic wire threading molybdenum wire cut EDM machine by NOVICK stands as a practical solution for production lines.

Focus on technology research and development to help China's intelligent manufacturing continue to move forward

Behind premium products lies the robust corporate strength and steadfast development philosophy. Beijing NOVICK has consistently upheld its technical service principle of "customer-first, service-oriented," with a research and development focus on "mastering core technologies while prioritizing customer experience." Rather than chasing flashy gimmicks, the company remains dedicated to one mission: "making machines intelligent partners that create value for customers." This remains NOVICK's unwavering corporate mission.

For nearly three decades, NOVICK has been dedicated to the high-end CNC equipment sector, delivering optimal solutions to industry leaders across new energy vehicles, aerospace, military electronics, and specialty materials. Its products are exported to over 20 countries and regions including South America, North America, Europe, and Southeast Asia, maintaining the highest export share in the special processing industry for consecutive years.

In today's manufacturing industry, intelligence, automation, and high precision are no longer optional but essential for enterprises to maintain competitiveness. If you're still struggling with low efficiency, poor accuracy, and inconsistent quality in manual threading, the AR2 Ultra series by NOVICK is the 'better solution' you've been seeking. The introduction of its automated threading system will usher in a new era for reciprocating threading technology.

NOVICK Service Hotline: +8610 6167 8811

Official website: www.novick.cn

IG/Facebook Official Account: NOVICK

línea directa de noticias en español: su fuente de noticias regionales y corporativas

© línea directa de noticias en español

política de privacidad